Products >> CNC numerical control machine series >>

Sponge CNC Ring Vertical Knife Imitation Cutting Equipment Foam CNC profiled cutting equipment Foam CNC cutting machine

- Product No.:20211112104821

Product description

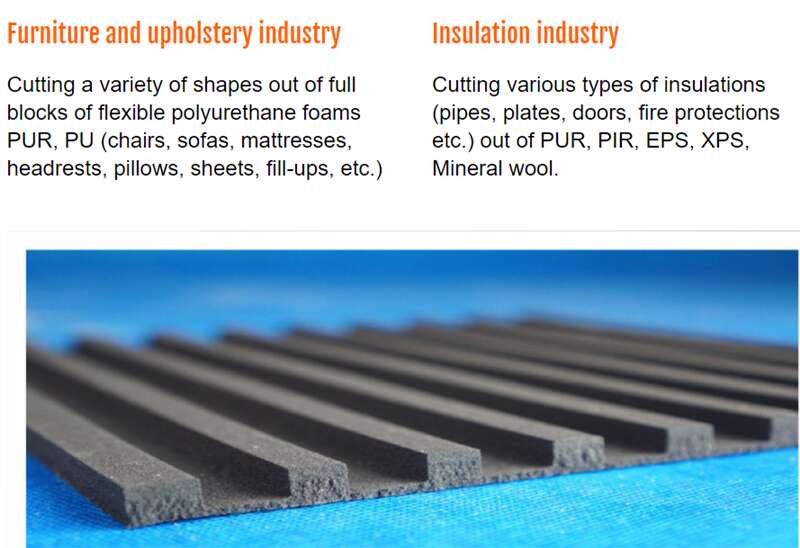

CNC FAST WIRE CUTTER | CUTTING SOFT AND RIGID FOAMS

A vertical knife is added on the original basis to realize simple three-dimensional cutting and replace a single punch die-cutting foam product without inner hole, which not only greatly improves the cutting accuracy of three-dimensional products and the working efficiency of die-cutting processing, but also fundamentally makes up for the disadvantage that similar machines that realize simple three-dimensional cutting through rotating worktable can not realize sheet special-shaped processing.

Applicable material:

Sponge products with various shapes and complex shapes.

The CNC Fast wire machines – are fully automatic, computer controlled machine with work principle based on endless running of abrasive (steel) wire which is sped up to 280 km/h to perform the perfect cut. The Fast Wire machines come with our own advanced electronic controllers based on ARM architecture and are connected to a PC via a USB port and then controlled with proprietary CNC application. Various cutting wire are available for different materials to obtain the optimal high quality and performance.

Dust free cutting any ideal geometric profile. It is suitable for automobile industry, furniture industry, packaging industry, construction industry, daily necessities, etc.

CAN EASILY HANDLE FULL-SIZE BLOCKS

CNC FAST WIRE SOFTWARE

All XTR fast wire CNC machines come with very user-friendly yet powerful control software. It is available in many different languages and constantly being improved and developed; plus, all customers receive free upgrades when new versions become available so they are always able to use the XTR fast wire cutter to its full potential.

Supports the following file formats:

plt – e.g. CorelDrawdxf – e.g. AutoCad

EPS/AI – e.g. AdobeIllustrator

How does the CNC fast wire cutter work?

Very simple! The drawings you wish to cut can be prepared in any graphics software able to export to one of the formats supported by machines control software. Once the drawing/project is opened in machines software all you have to do is set cutting parameters (such as speed, etc.) and click Simulate or Cut (start).All simple cuts and trimming operations can also be performed with the use of the included wired remote controller, so often there is no need to prepare any drawings whatsoever.

Included with all XTR units!

Available in many different languages!

Free, unlimited upgrades! Unlimited parameters libraries!

Compatible with Windows XP, Vista, 7, 10!

User-friendly interface, easy-to-use yet powerful!

On-screen cutting simulation!

Cutting time estimates! Built-in duplication feature!

Full manual control for simple cuts not requiring a drawing!

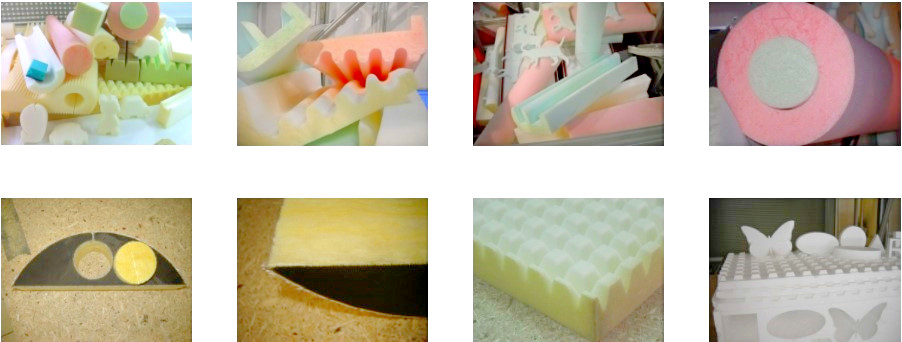

CUTTING SAMPLES

The Fast wire cutting technology is a dusty one as the abrasive wire moving at high speed creates a lot of dust in yhr process.

For those unable to connest the machine to their factory industrial dust suction system, we offer a stand-alone dual bag (7HP / 3-phase) system with 10 meter section of 100mm hose and a special dust collecting metal piece to be installed on the machine. It wont collect 100% of the dust, but it will help significantly.

WARRANTY

All cnc fast wire cutters are covered by a complete 12-month warranty. During this time manufacturer bears all costs related to spare parts and their shipment. The only parts not covered by the warranty are the consumables – the actual fast wires and the wheels which wear off over time. Additionally, each customer receives free unlimited upgrades of the FastCutter software so the machine can always be used to its full potential.

System parameters:

|

Weight(T)

|

1.3

|

Type of CNC

|

Industrial computer

|

|

Full Power

|

6KW,380,50Hz |

Display

|

LCD

|

|

Size(mm)

|

5200*3200*2300

|

Controlling module

|

Motion controlling card

|

|

Max foam size(mm)

|

2200*2200*1200

|

Operation system

|

Windows2000及以上

Windows2000 or above |

|

Blade size(mm)

|

2500*3*0.5

|

Programmable axis

|

X,Y,Z,Ф

|

|

Max-cutting-Speed(m/min)

|

0-10

|

Step motor torque

|

20

|

|

Admissible error(mm)

|

±0.5

|

Min-cutting-radius(mm)

|

10

|

|

Mincutting size(mm)

|

5

|

Self-test system

|

Install

|

|

Table

|

Rotary

|

Blade alert

|

Install

|

Products Category

Contact Us

Name: Dylane shi

E-mail: [email protected]

QQ: 627812212

WeChat: qd627812212

Whatsapp: +8618061811323

Add: Qingdao City, Shandong

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online