Products >> Foam foaming machine series >>

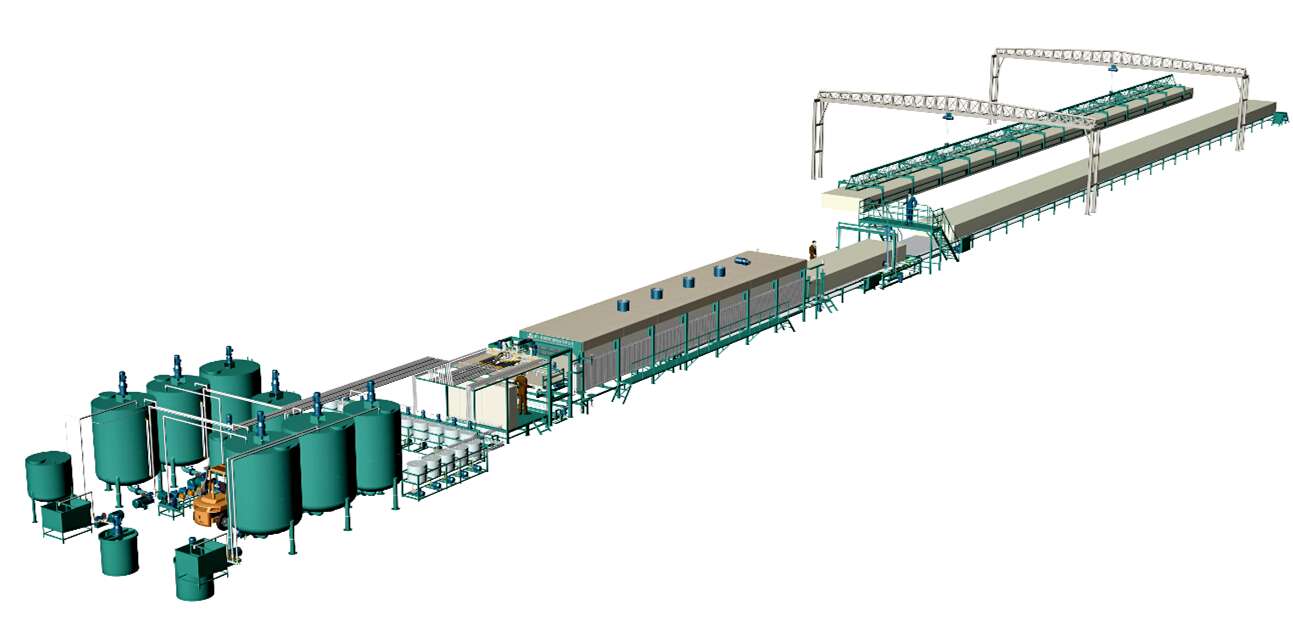

HXW-CTXZD2400Horizontal automatic continuous foaming production line

- Product No.:2021118

Sponge automatic horizontal continuous foaming production line is mainly applicable to the production of soft polyurethane sponge with density range of 7-160kg / m3.

1、The machine adopts a man-machine interface control system with high degree of automation and more flexible Mastery (the machine has two configurations: automatic manual control and automatic man-machine interface). Users can store 200 different formulas, adjust or change the formulas at any time, and remotely control through the Internet to make the control of production cost more scientific and intuitive.

2、The formula of the equipment can be changed directly without stopping the machine. The flow does not need to be measured. The yellowing resistance can reach level 3 international standards. It is used to produce all kinds of ideal furniture cotton, shoe cotton, chest cotton and electronic cotton, as well as all kinds of sponges suitable for packaging, clothing and automobile industry. Cooperate with the manufacturer to provide training on formula and foaming technology

|

Oven length |

17.5m |

|

Foam height |

<1.25m |

|

Foaming width |

1250mm-2350mm |

|

Foaming density |

10-50kg/m³ |

|

Total power |

150kw |

|

LinKing conveyer belt length |

17.5m |

|

Side board adjustable width |

0.98-2.3m |

|

Conveyer belt speed |

3500mm/min-6800mm/min |

|

Mixing-head power |

37kw |

|

Total output |

100-300kg/min |

|

Machine external size (LWH) |

L34000×W4550×H3200MM |

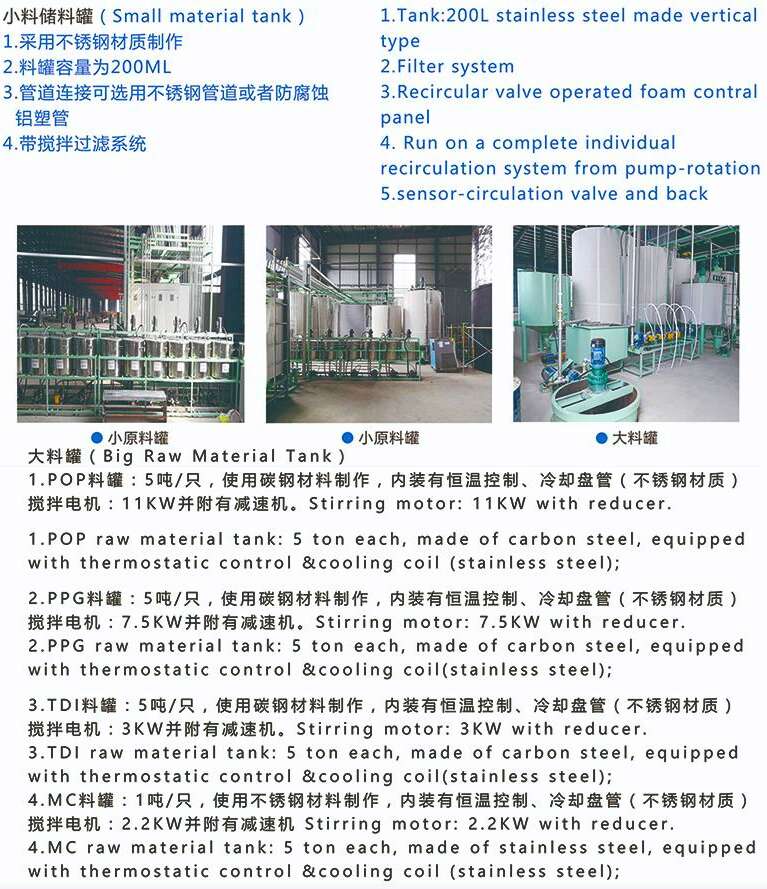

Components of foam foaming machine - large raw material tank

|

type |

purpose |

Specifications |

|

Large raw material tank |

PPG、Calcium powder |

5m3 with constant temperature and mixing system, made of A3 carbon steel |

|

Large raw material tank |

POP |

5m3 with constant temperature and mixing system, made of A3 carbon steel |

|

Large raw material tank |

TDI、MDI |

3m3 with constant temperature and mixing system, made of A3 carbon steel |

|

Large raw material tank |

MC、Fireproof oil |

1m3 with constant temperature and mixing system, made of A3 carbon steel |

Small auxiliary raw material tank

Small raw aterial tank

Amine, diethanolamine, tin, silicone oil 1, silicone oil 2, H2O, color 1, color 2, color 3, black material, etc

180L, with constant temperature and mixing system, made of 304 stainless steel

Calcium powder tank

Calcium powder mixing tank

2M3

Cleaning tank

MC

Pressure tank (cleaning)

Small raw aterial tank

Amine, diethanolamine, tin, silicone oil 1, silicone oil 2, H2O, color 1, color 2, color 3, black material, etc

180L, with constant temperature and mixing system, made of 304 stainless steel

Calcium powder tank

Calcium powder mixing tank

2M3

Cleaning tank

MC

Pressure tank (cleaning)

Products Category

Contact Us

Name: Dylane shi/ Henry

E-mail: [email protected]

QQ: 627812212

WeChat: qd627812212

Whatsapp: +8618061811323

Whatsapp: +8613210076180

Add: Qingdao City, Shandong

CHINESE

CHINESE ENGLISH

ENGLISH

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online